how plasma cutter machine works

This is focused toward beginners and shows basic tec. It transfers the arc power to the workpiece.

When this electrode touches the workpiece.

. The gas can be shop air nitrogen argon oxygen etc. Once the plasma gas compressed air builds up enough pressure the electrode and nozzle are forced apart which causes an electrical spark that converts the air into a plasma jet. Ad Read Expert Reviews Find Best Sellers.

The plasma cutting system of your machine senses this situation and stops the arc between the electrode and the nozzle and facilitates the flow of current from the electrode to the. CNC plasma cutter is an automated cutting machine. The main advantage of a plasma cutting machine is that it cuts small thicknesses of metal workpieces.

This current and airflow continues until the trigger is. Find and Compare the Best Plasma Cutters Based on Price Features Ratings Reviews. How Does a Plasma Cutting Machine Work.

During this process an electrical current travels through this gas creating an arc between the workplace and an electrode. And it enters the fourth state of matter. The high heat causes the workpiece to melt and be blown off forming a working state of plasma arc cutting.

Plasma cutting torches use a copper nozzle to constrict the steam of plasma which is then subjected to the workpiece. Plasma cutting is the process of cutting material by pushing melted down ionized gas set at twenty-thousand degrees or more through the opening of a plasma cutting machine. Beginners guide to plasma cutting.

Any name along with CNC is an example of the automation technology. The overall mechanics of the system is always the same. Plasma cutting uses plasma to heat the metal to be cut to a molten state and then uses an auxiliary gas to blow the molten metal away to achieve the cutting purpose.

Advantages of Plasma Cutting. Plasma cutters use compressed air or other gases such as nitrogen. Which means that is uses heat to melt the metal instead of mechanically cutting it.

Consequently A CNC Plasma cutter is an automated plasma cutter machine which has a plasma cutting tool. Learn how a plasma cutter works the gases used in cutting what metrical can be cut and the uses of this machine. Plug in the plasma cutter.

We are known to the first three states of matter- solid liquid and gas. Get 2-Day Shipping Free Returns. The principle of plasma is to change from state to liquid water then.

It is passing through a constricted opening. The plasma stream is typically formed by forcing a gas such as nitrogen oxygen argon or even air through a narrow nozzle. We all are known with the three.

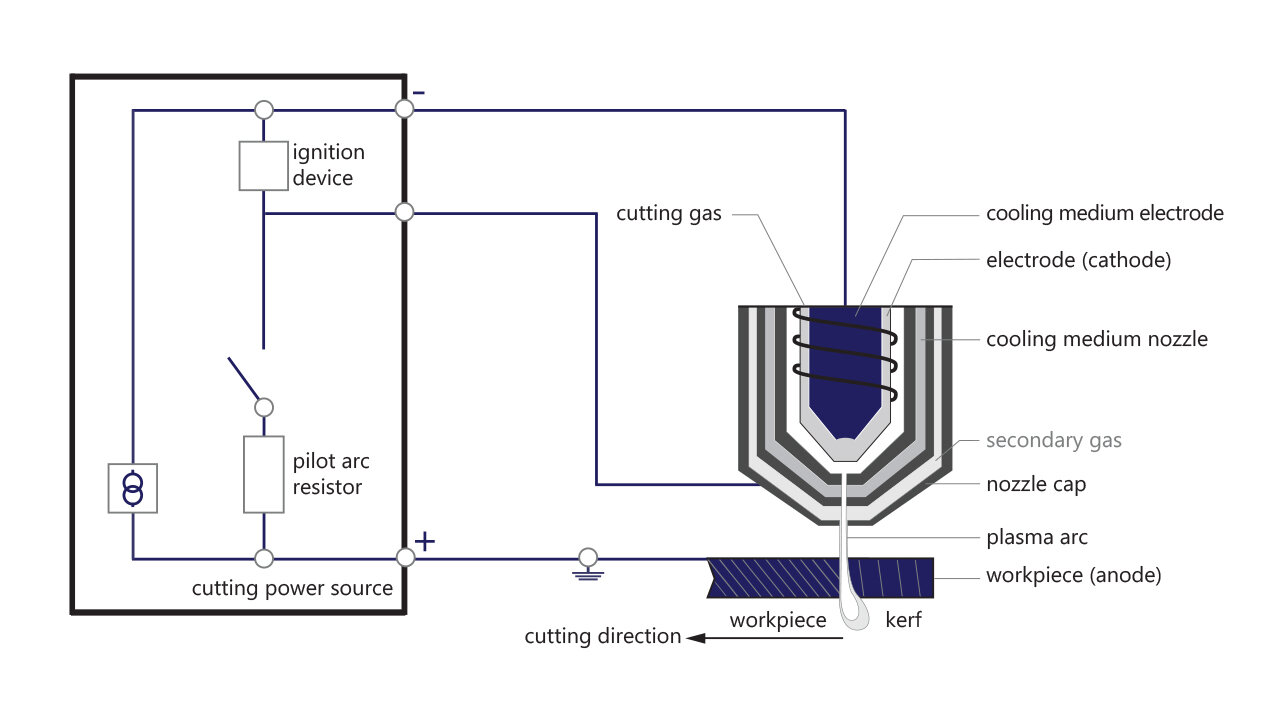

A secondary gas jet subsequently blows the melted material out of the kerf. Plasma torch The function of the plasma torch is to provide proper alignment and cooling of the consumables. The plasma cutters work by transferring an electric arc through a gas.

After the compressed air enters the torch two channels are distributed from. Plasma cutting machine plasma is heated to a very high temperature in the highly ionized gas in the transfer of it from the arc power to the workpiece the high heat makes the workpiece melted and blown off the formation of the plasma arc cutting work. The gas from the air compressor is required for the plasma cutter to function.

This ionizes the gas electrically charging. 10 Times Faster Than Traditional Cutting. Plasma cutting speed especially in cutting.

After plugging it in you can connect the external air compressor to the unit. We get out the Miller Spectrum 375 Plasma Cutter and Give you a lesson in HOW TO USE A PLASMA CUTTER. Engineered To Automate Every Aspect Of Your Structural Fabrication Increase Productivity.

It elevates the temperature of the gas to the point. The DC current flow then switches from electrode to nozzle to a path between the electrode and work piece. Hypertherm plasma cutter for CNC machines.

This elevates the temperature of the gas to the point that it enters to the fourth states of matter. Ad Iron Workers Coping Machines. Also called a thermal cutting method cnc plasma cutting machine china can cut metals which are good conductors of.

Then you can turn the air compressor on. Stop outsourcing your cutting needs and put a production capable machine in your shop. An additional shielding cap may be used to further improve cut quality and all the parts are held together by inner and outer.

An electric current produced by an external power supply adds sufficient energy to the gas flow to. At the same time compressed gases blow away the molten metal. Plasma Cutter comprises a constricted opening through which an electric arc is sent through a gas.

How plasma cutting machines work. The gas can be shop air argon nitrogen oxygen etc. A plasma cutting system works with compressed gas fed through a hose and into a small channel in the torch.

Where the plasma jet touches the to-be-cut object it transmits its energy and punctually melts the material. Solid gas and liquid. Ad Featuring Powered Z-Axis Software Stainless Steel Water Table and Torch Height Control.

Then an electrical arc much like whats used in a welding machine once again is sparked up. As the current from the cutting torch passes through the plasma sufficient heat is produced to melt through the workpiece. A plasma is a gas that is heated to a very high temperature and is highly ionized.

Double check and make sure that the divide power is off before plugging it in. How plasma cutting works. What a Plasma Cutter Does.

Plasma cutting is one effective method. Inside the plasma torch is a negatively charged electrode. Ad Get the best cut quality possible.

However after the 19 th century we got the advancement of the various CNC machines. How Plasma Cutting Machines Work. The main consumable parts required for plasma arc generation are the electrode swirl ring and nozzle.

The nozzle of the plasma cutter is used to blow the gas at high speeds toward the work surface. A plasma cutter or plasma cutting system uses a plasma stream to transfer energy to a conductive work material. The plasma cutting process is a thermal cutting method.

CNC means computer Numeric Control.

Tomahawk 625 Plasma Cutter With Machine Torch Plasma Cutter Plasma Torch

How Does A Plasma Cutter Work Youtube

Metal Working Plans Ideas To Boost Your Arts And Crafts Projects Cnc Plasma Cnc Plasma Table Cnc Plasma Cutter

Plasma Cutting Info On Plasma Technology

How Plasma Cutting Works Advantages Disadvantages Fractory

View Topic Diy Plasma Cutter 3 8 Capable And Under 100 Plasma Cutter Free Energy Generator Diy Projects For Men